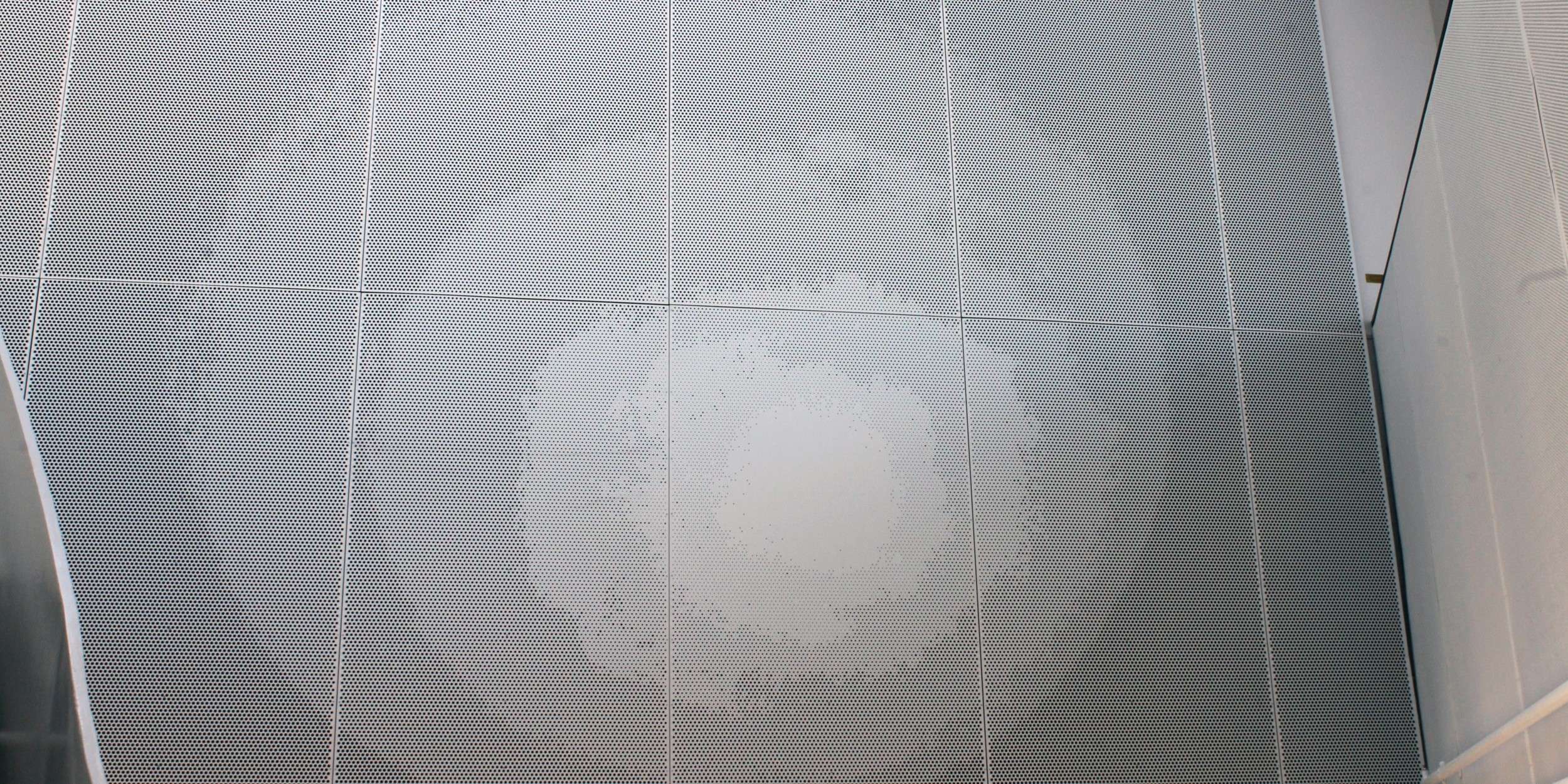

DAMPA creates a variety of acoustic solutions for ceilings and walls. What all these solutions have in common are the perforations in the metal. We can’t do without them, but why are they there? What significance do they hold? Let’s take a closer look here.

DAMPA manufactures all our acoustic solutions in either steel or aluminium. We’ve been doing this for over 70 years now. One of the questions we often hear is: how can metal be acoustically effective?

This is where the perforations come into play and play a crucial role.

A world of difference for the acoustic experience

When DAMPA creates an acoustic element for the ceiling or the wall, the thin metal panel becomes the membrane absorber.

By perforating the robust surface of the metal, we add two additional absorbers: the porous absorber and the resonance absorber.

The porous absorber comes in the form of our acoustic felt, accessible through the perforations.

As for the resonance absorber, this is where the perforation shines. Within each perforation are small “air plugs” that vibrate against the acoustic felt and the cavity behind it.

By combining the hard surface with the perforations and the underlying acoustic felt, we activate all three types of absorbers – thereby integrating the best of acoustic principles into all our acoustic solutions and ensuring optimal acoustic performance.

You can read more about these three types of absorbers in this article.

Considerations when choosing perforations

At DAMPA, we offer over 30 different perforation designs. However, the choices available depend on the product type you intend to use in your design.

For example, our cassettes typically have a larger surface area where we can perforate compared to our lamellas. Therefore, we can experiment with various sizes and shapes of perforations with our cassettes.

Additionally, we need to consider the material. The size of the perforation affects the strength of the material. A larger perforation weakens the material, so it’s necessary to increase the thickness to maintain durability and aesthetic appeal.

Read more about the different perforation possibilities in our brochure.

Large perforations do not enhance acoustic performance

A common misconception is that larger perforations lead to better acoustic ratings.

However, this isn’t the case.

When perforations are too large, they affect the resonance and membrane absorption, resulting only in what we call acoustic transformation, where the metal loses its impact on acoustic performance.

We do not recommend perforations larger than 10 mm in diameter, as beyond this size, they become more decorative than functional for acoustics.

Perforations are crucial for a good indoor climate

When discussing a good indoor climate, we focus on three aspects: acoustics, temperature, and ventilation.

As we’ve just stated, perforations have a positive impact on acoustic performance. They also contribute positively to temperature and ventilation. Our perforations are particularly effective in diffuse ventilation scenarios.

Diffuse ventilation involves creating positive pressure above the ceiling, pushing fresh air down through the ceiling. Our perforations spread across the panel, help distribute air evenly, preventing drafts and ensuring effective ventilation.

Looking at DAMPA® Climate Ceiling, perforations play a minor role in radiant heating and maintaining optimal temperature. Here, the metal panel itself plays a crucial role due to its rapid response to temperature changes.

By combining our perforated metal ceilings with diffuse ventilation and DAMPA® Climate Ceiling, we create a ceiling surface that addresses acoustics, ventilation, and temperature without compromising on design, functionality, or indoor comfort.

Key Points

- Perforations are crucial for the acoustic effectiveness of DAMPA’s acoustic solutions.

- Perforations create two types of absorbers: porous and resonance absorbers.

- DAMPA offers over 30 different perforation designs, but the options vary depending on the material and product type.

- Larger perforations do not necessarily improve acoustic ratings.

- DAMPA recommends avoiding perforations larger than 10 mm in diameter as they lose their acoustic effectiveness.

- Perforations work well with diffuse ventilation systems, preventing drafts and ensuring even air distribution.

- Combining perforated metal panels with diffuse ventilation and DAMPA® Climate Ceiling provides a solution that addresses acoustics, ventilation, and temperature effectively.