- Reduce – reuse – recycle

Sustainability

Would you like to talk to someone about our work with sustainability?

Fill out your details and one of our experiences employees will be in touch.

We contribute to regenerative design

At DAMPA we continuously work on improving the sustainability of our products and solutions. Steel and aluminium are heavy raw materials to extract, but when focusing on recycling, the materials can be beneficial to our planet. Once the metal is extracted, it can, with relatively few resources, be recycled repeatedly without leaving the circular cycle.

At the same time, our products have a long service life. It favours the environment by reducing resource consumption and thus the emission of CO2 and greenhouse gases.

In our work with sustainability, we thus work with a “Reduce-Reuse-Recycle”-approach.

DAMPA in the certified building

As a climate-conscious partner, DAMPA can also contribute to environmentally certified buildings, as all our ceilings in steel and aluminium including our climate ceiling has environmental product declarations (EPDs). The EPDs can be used for building certifications in e.g. LEED, BREEAM and DGNB building projects and make it easy to get an overview and compare different environmental properties of products.

The American certification LEED (Leadership in Energy and Environmental Design) can be used for commercial as well as private buildings and infrastructure. LEED is an assessment of whether a building achieves high standards in categories such as energy and water consumption.

The Building Research Establishment Environmental Assessment Method (BREEAM) is one of the most widely used certification systems for sustainable construction. BREAAM can be used for commercial as well as private constructions and infrastructure.

The German DGNB certification is the most used in Denmark. It is a holistic certification system which focuses on the entire life cycle of a building. It incorporates environmental, economic, socio-cultural, technical and process-oriented factors.

Download our EPD's

The EPD documents the product’s environmental performance properties. The environmental properties are based on the total emissions and resource consumption, including CO2, energy, water and waste generation, calculated over the product’s life cycle.

Acoustic solutions in climate-friendly aluminium

DAMPA focus on sustainable initiatives, which, among other things, involves a completely new aluminium that has a 69% lower CO2 emission.

“We constantly focus on improving our work to minimize our carbon footprint. One of the solutions we have recently introduced is our “greener” aluminium. If you compare our current aluminium with, for example, aluminium from the Far East, our material from European suppliers derives 57% less CO2 per kg.” Mogens Kjærgaard, Head of R&D and Sustainability at DAMPA explains and adds:

“Now we can also offer a solution based on “Post Consumer Aluminium” which is an even greener solution. By using aluminium which consists of 75% recycled material, the CO2 footprint is further lowered by 69%. We look forward to enlarging our production with green aluminium, and thus deliver even greener solutions for the Danish construction industry.“

Fossil-Free steel in Sight

When we produce solutions in steel it is often produced in material from SSAB.

SSAB is currently working towards their goal of a fossil free steel production by 2030:

“The full scale production of fossil free steel is expected to be up and running in 2030. Meanwhile DAMPA will gladly participate in test and pilot projects together with SSAB towards the zero emission acoustic products made of steel. And this is not just a crazy dream – I’ve had the product in my hand.” CEO, Michael Nykjær shares.

We follow the development closely and are excited to see what the future holds for durable fossil free steel solutions.

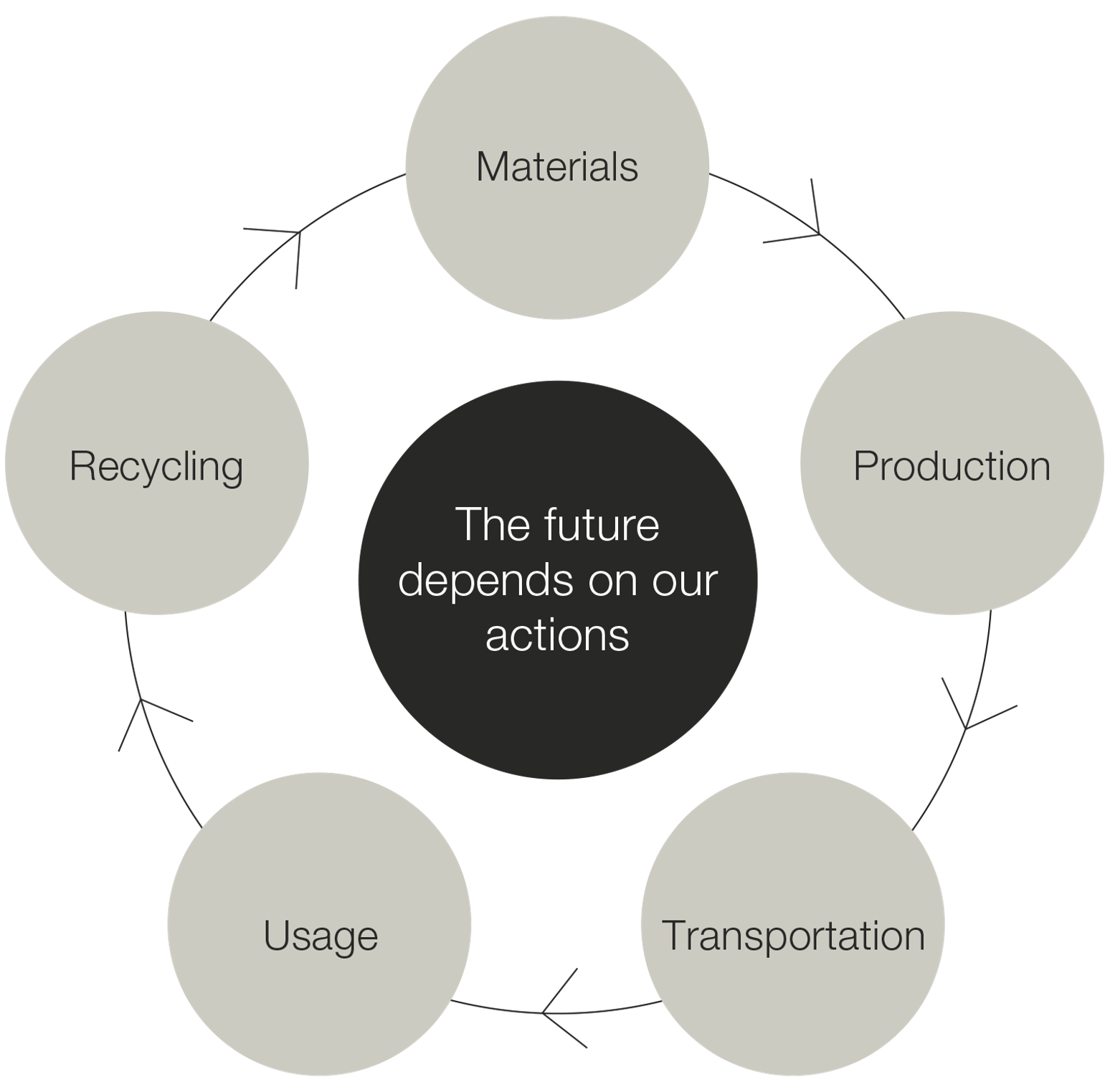

DAMPA’s product lifecycle

- Materials

We use Northern European raw material suppliers who meet the highest environmental standards. A large part of the raw materials we use for production is recycled material. - Production

Our production is located in Denmark. The varnish used for our ceilings is VOC-free. All internal metal waste is collected and recycled. - Transportation

We have relatively short transport between suppliers and our production. Furthermore, we are continuously working on our packaging procedure to ensure that we use as little material as possible. - In use

Our ceilings contribute to a good indoor climate on several parameters: sound, aesthetics, light, temperature and ventilation. Our ceilings are produced in metal and therefore have an extremely long life. - Re-usability

Our ceilings can be reused as they can be dismantled and set up in a new location. In addition, our ceilings can be recycled and once again form part of the circular cycle.

We use power from wind turbines

This means that our production and administration only use power from wind turbines.

Contact

the perfect solution for your next project.